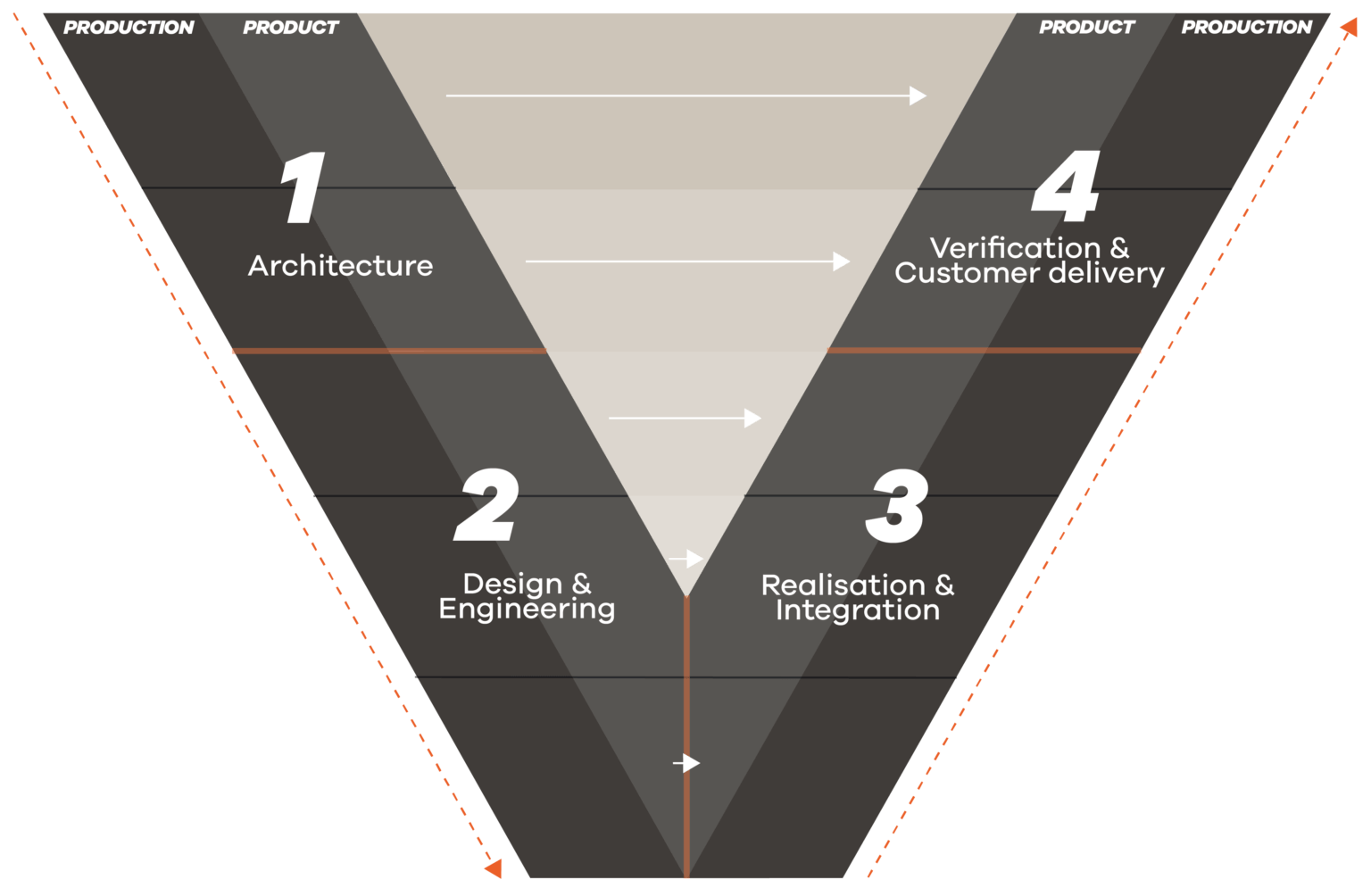

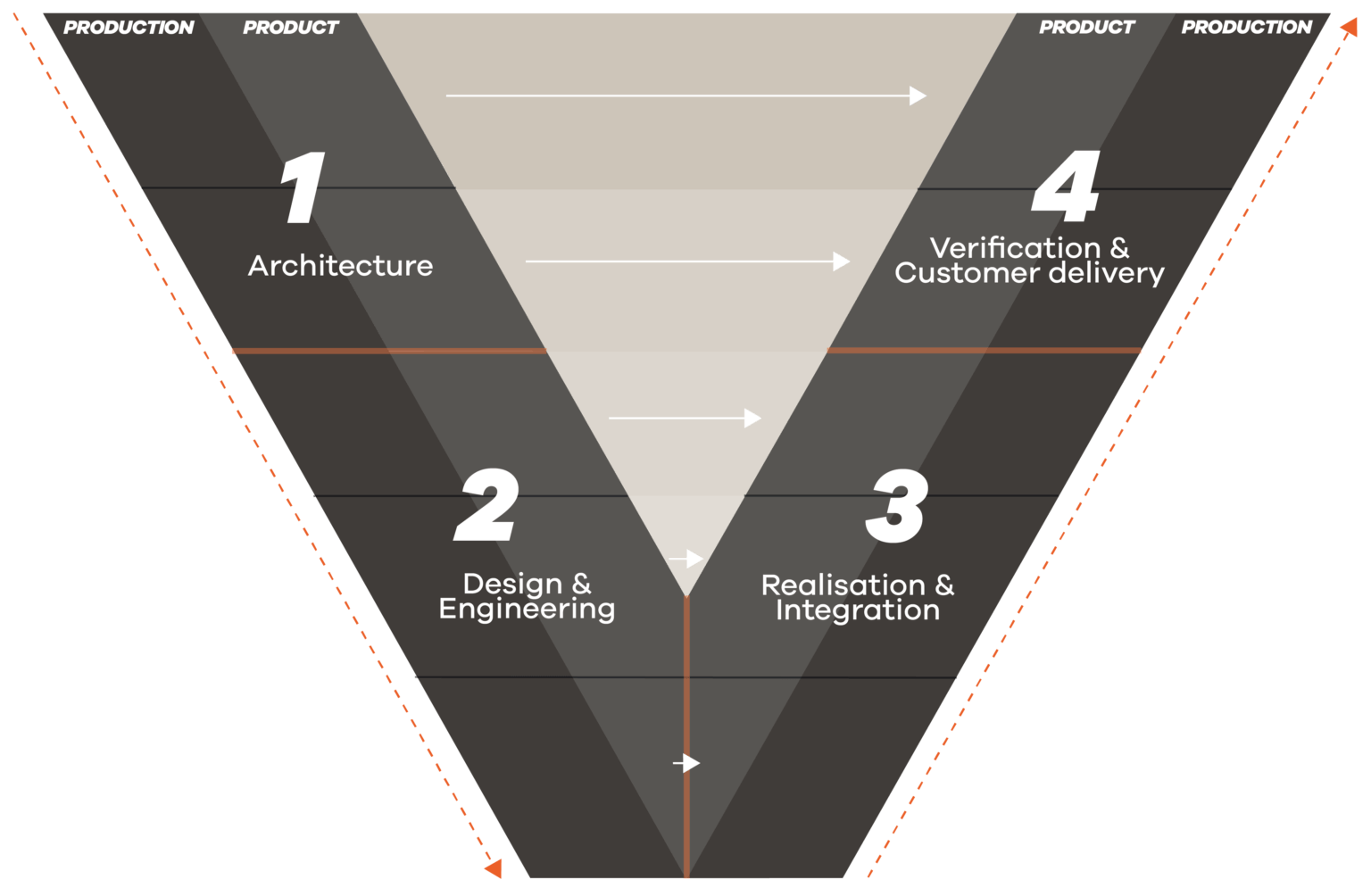

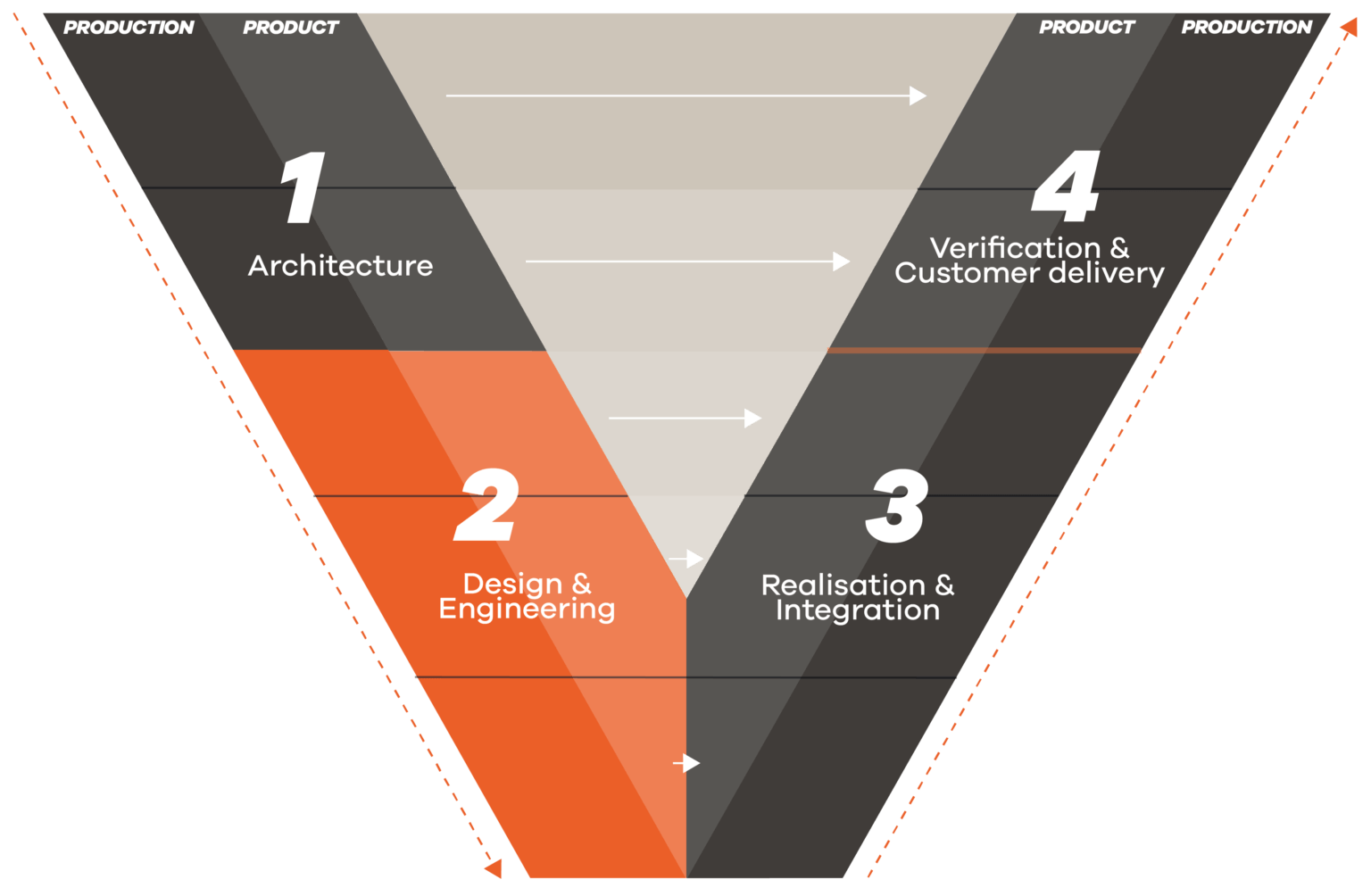

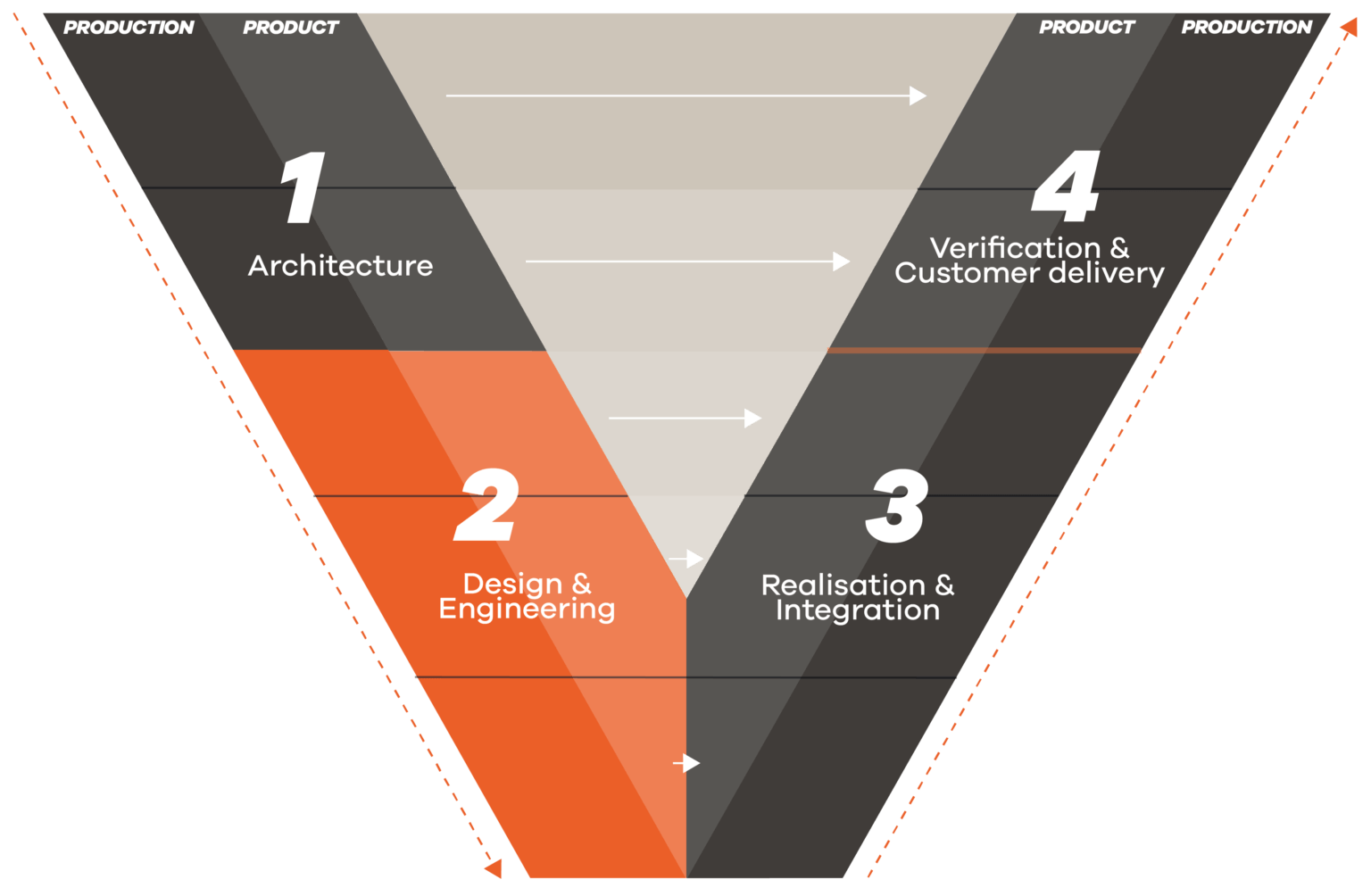

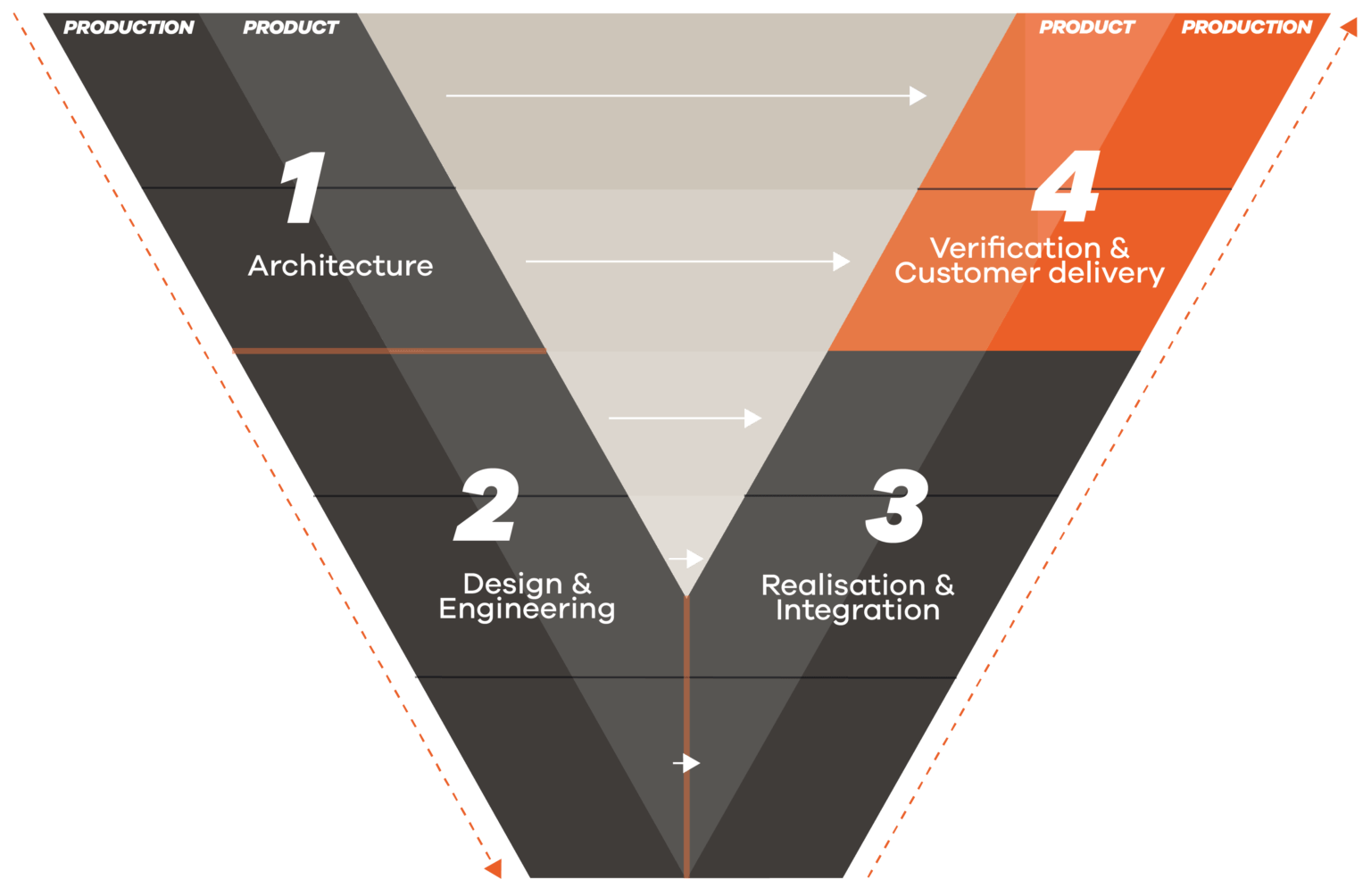

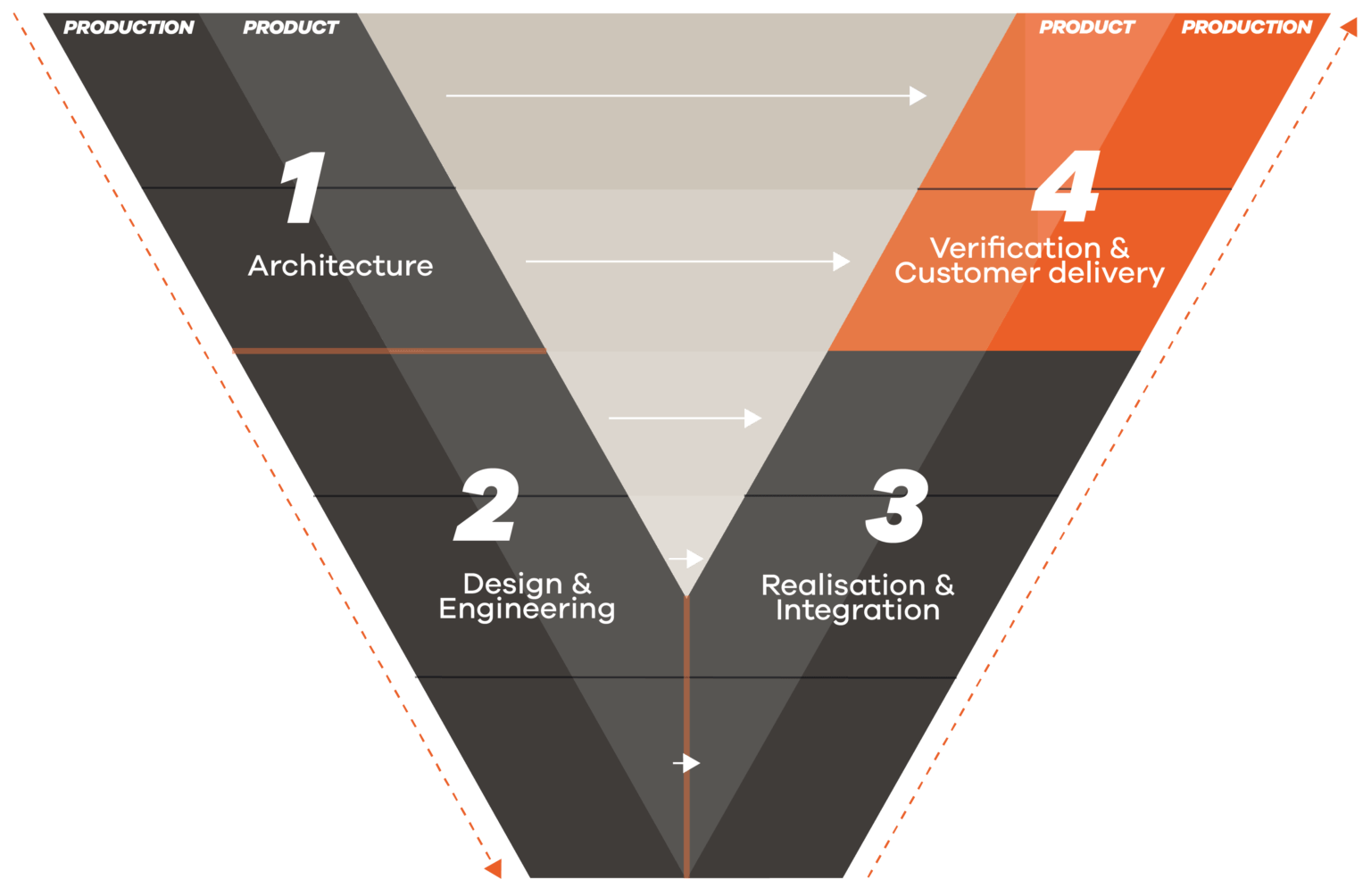

At MTA, we believe in the added value of connecting product development and production. From this philosophy, the unique V² model was developed. Traditionally, the development of a high-tech system follows the classic V-model, delivering a technically functional solution in the form of a validated prototype.

Next, the focus shifts to how the system can be produced in series. It often becomes apparent that too little knowledge and expertise from the production process was incorporated during system development. The result is a design that is difficult to reproduce and production costs that are much higher than anticipated. To avoid this, it is essential to consider manufacturability, production costs, and all other factors involved in series production from the very beginning of the product design. This is how our unique V² model was born. Want to learn more? Scroll down or download our whitepaper.

We follow our unique V² model, where product development and production design run in parallel and are continuously aligned throughout the development process. Connecting product development with production results in a better, faster, simpler, and therefore more cost-effective solution.

At MTA, we believe in a different way of working. In the traditional V model, too little knowledge and expertise from the production process is incorporated. We believe that connecting product development with production development leads to a better, faster, simpler, and therefore more cost-effective solution. That’s why we’ve developed our own V model specifically for production design. By bringing these two V’s—product and production—together and running them simultaneously, we have created our unique V² model.

At MTA, we believe in a different way of working. In the traditional V model, too little knowledge and expertise from the production process is incorporated. We believe that connecting product development with production development leads to a better, faster, simpler, and therefore more cost-effective solution. That’s why we’ve developed our own V model specifically for production design. By bringing these two V’s—product and production—together and running them simultaneously, we have created our unique V² model.

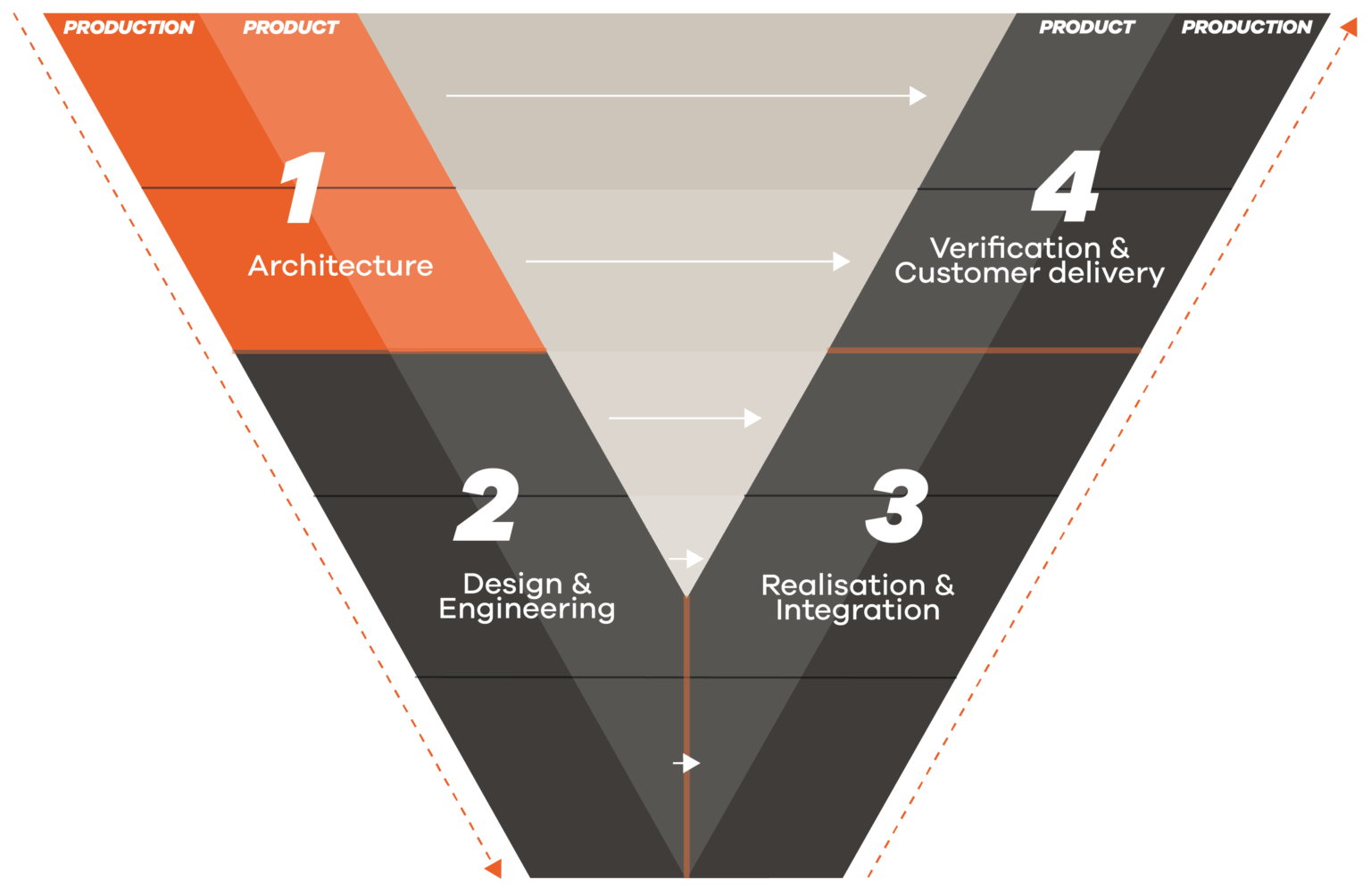

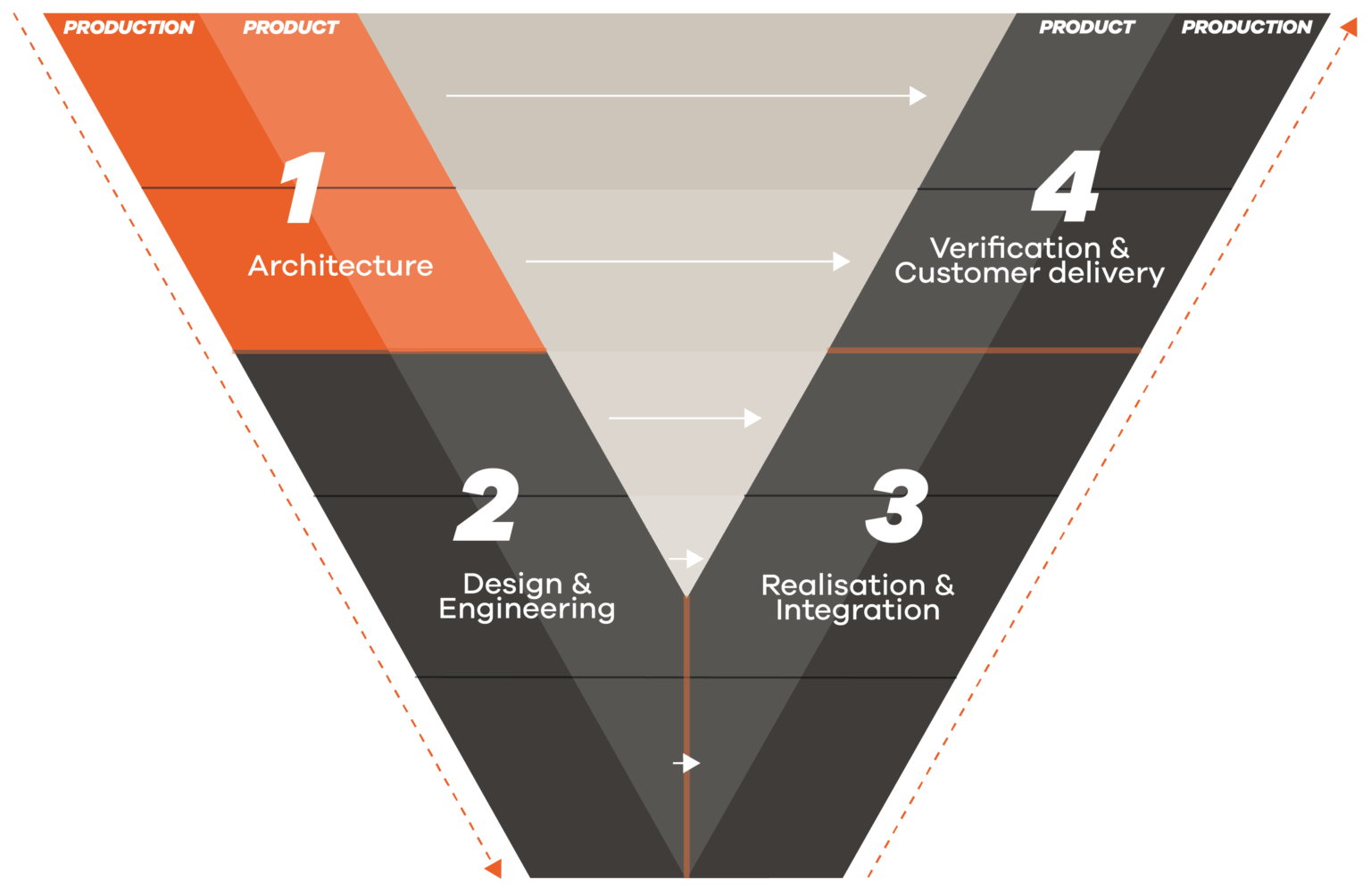

In phase 1 of the V² model, the technical customer requirements and product and production conditions are translated into the appropriate system architecture. Additionally, we carefully consider which production techniques best match the intended production volumes and determine the purchasing strategy, assembly philosophy, and distribution approach.

In phase 1 of the V² model, the technical customer requirements and product and production conditions are translated into the appropriate system architecture. Additionally, we carefully consider which production techniques best match the intended production volumes and determine the purchasing strategy, assembly philosophy, and distribution approach.

In phase 2, the architecture is further detailed, with a thorough examination of whether functions are standard or customized. Within the V² model, we work modularly, where the separate testing and assembly of modules are key requirements.

We involve our entire supply chain and determine the production techniques. QLTC criteria (Quality, Logistics, Time, and Cost) are defined. Phase 2 concludes with a complete Technical Product Documentation (TPD).

In phase 2, the architecture is further detailed, with a thorough examination of whether functions are standard or customized. Within the V² model, we work modularly, where the separate testing and assembly of modules are key requirements.

We involve our entire supply chain and determine the production techniques. QLTC criteria (Quality, Logistics, Time, and Cost) are defined. Phase 2 concludes with a complete Technical Product Documentation (TPD).

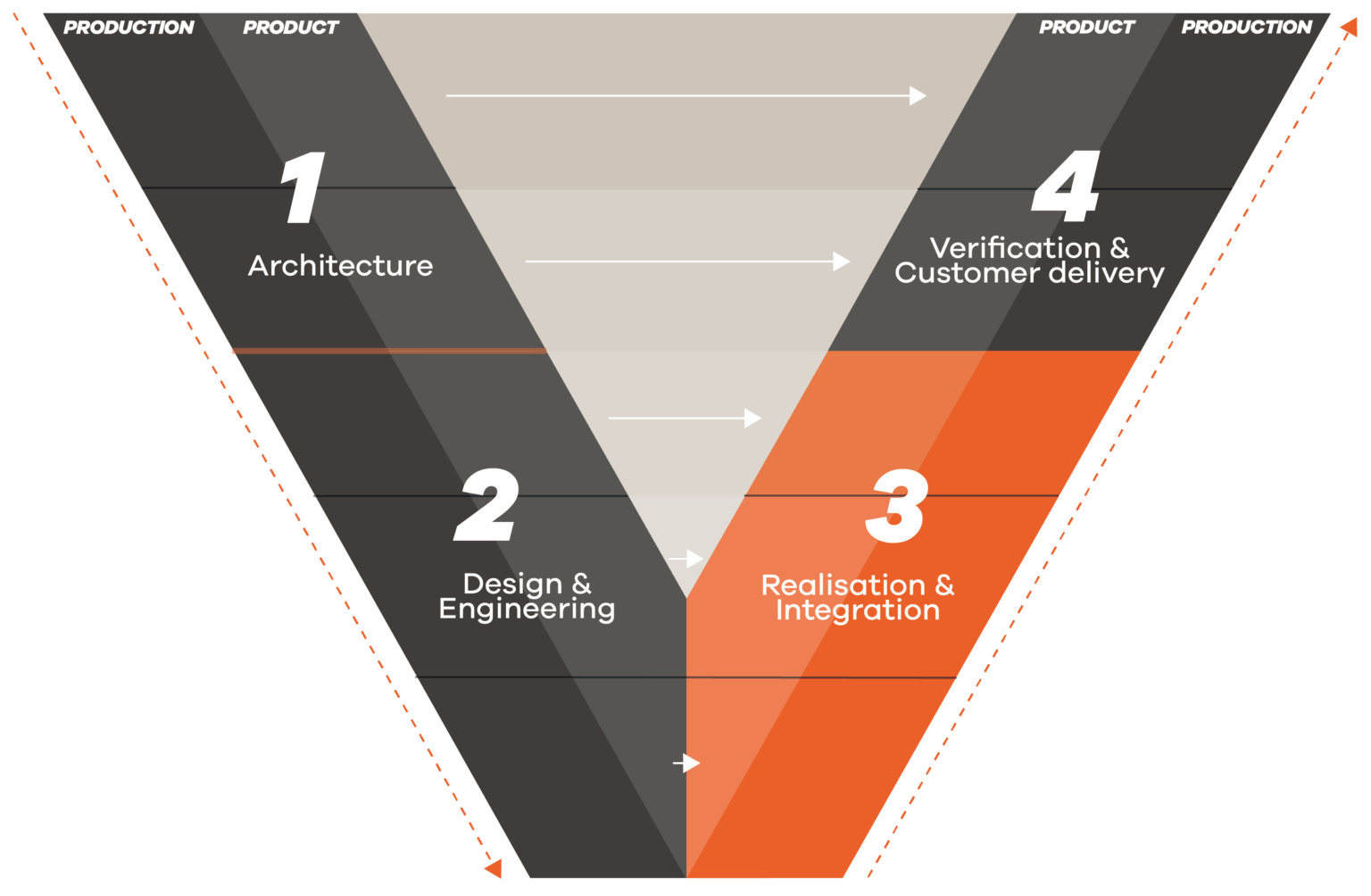

In phase 3, the detailed design comes to life and realization begins. We work from components to units, combine units to create a module, and then assemble the various modules into the final product. Design checks are performed, and any issues are analyzed.

We begin using ERP, PLM, and CCB systems. Work instructions are created, and technicians are trained. A prototype is assembled.

In phase 3, the detailed design comes to life and realization begins. We work from components to units, combine units to create a module, and then assemble the various modules into the final product. Design checks are performed, and any issues are analyzed.

We begin using ERP, PLM, and CCB systems. Work instructions are created, and technicians are trained. A prototype is assembled.

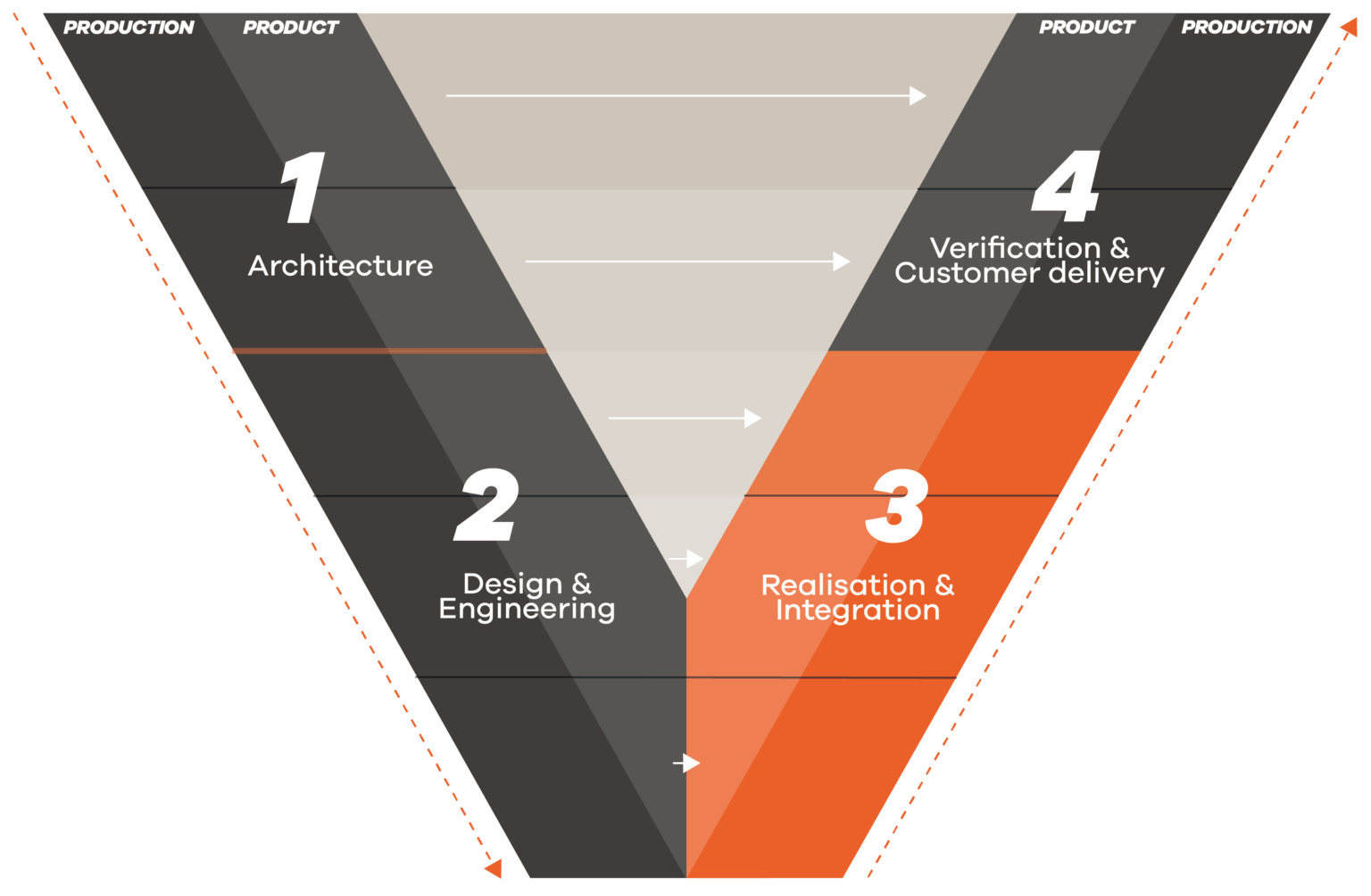

In phase 4, the product design is improved based on test results and new insights. Systems are integrated, and designs are validated.

Production finalizes the plans for series production based on the lessons learned from the prototypes. Verification and delivery are also combined in the V² model, ensuring that the impact and lead time to series production remain minimal.

In phase 4, the product design is improved based on test results and new insights. Systems are integrated, and designs are validated.

Production finalizes the plans for series production based on the lessons learned from the prototypes. Verification and delivery are also combined in the V² model, ensuring that the impact and lead time to series production remain minimal.

Discover how connecting product development and production increases the chances of a successful launch! (Dutch only)