DESIGN WITH PRODUCTION IN MIND

Industrialization

The majority of a product's cost is determined by the design (TPD) and is influenced by the architecture and concept choices made during the development process. Although industrialization should ideally be integrated into the Product Creation Process (PCP) from the start, for various reasons, it may be necessary to implement an industrialization phase later on, or even during the product lifecycle.

THE DESIGN DETERMINES THE MAJORITY OF THE COST PRICE.

COST REDUCTION IS NOT JUST ABOUT NEGOTIATING LOWER PRICES

The majority of a product's cost is determined by its design (TPD). Therefore, cost reduction is not only about negotiating lower prices but also about making smart choices throughout the entire process.

An industrialization process can help shorten lead times, minimize waiting times, and reduce manufacturing costs. For example, improving manufacturability leads to a more efficient production process and, consequently, lower costs.

Depending on the customer's needs and requirements, we can also implement improvements in product quality, functionality, standardization, configuration management, or sustainability.

INDUSTRIALIZATION SOLUTIONS

Within our one-stop factory, we have all the competencies needed to execute an industrialization process. The further we go back in the design phase, the bigger the impact we can achieve.

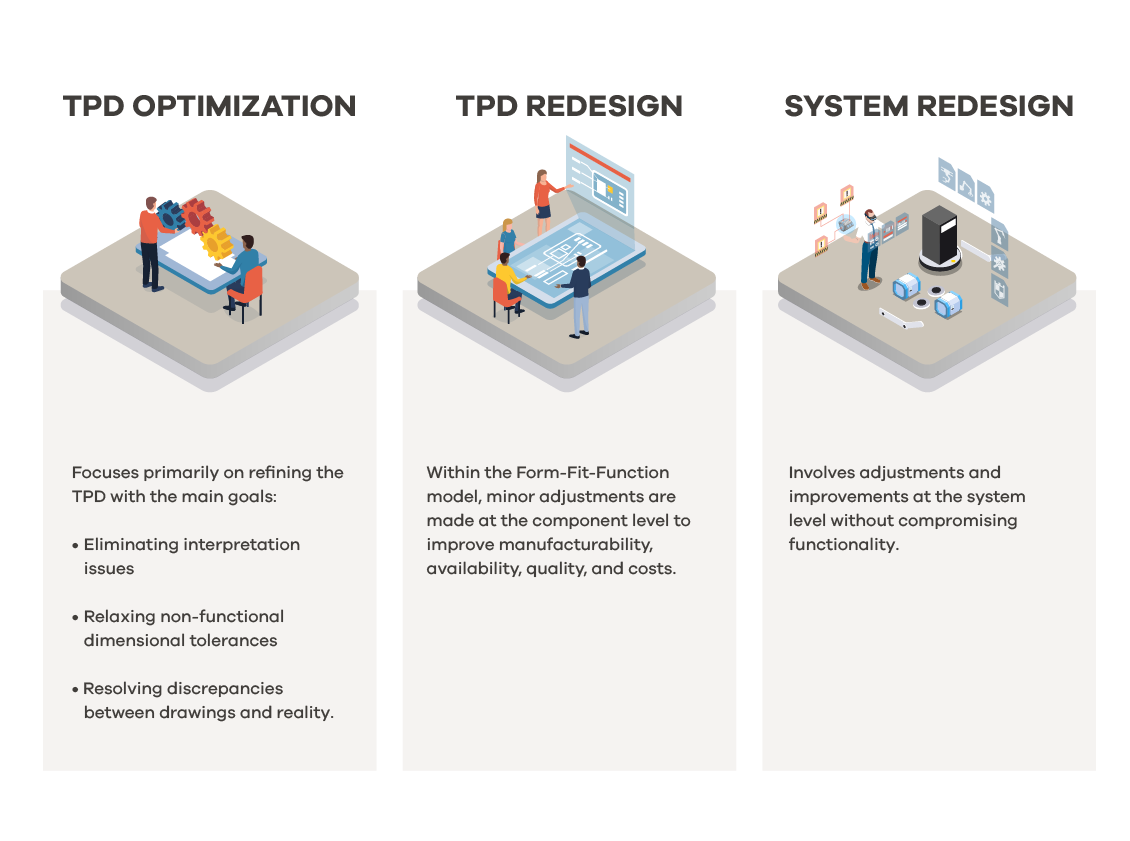

We distinguish between three levels: