The Company

AM-Flow is a start-up focused on the 3D printing market. The company creates intelligent solutions designed to simplify large-scale 3D printing processes. So far, several systems have been developed, including the AM Vision 2.0.

AM-Flow specializes in artificial intelligence and machine learning. MTA was selected as the partner for both engineering and production of the AM Vision 2.0. We achieved a short time-to-market and developed a system that is highly suitable for series production.

AM-Flow is a start-up focused on the 3D printing market. The company creates intelligent solutions designed to simplify large-scale 3D printing processes. So far, several systems have been developed, including the AM Vision 2.0.

The challenge was to design and produce the AM Vision 2.0 system within a short timeframe while meeting the required quality standards.

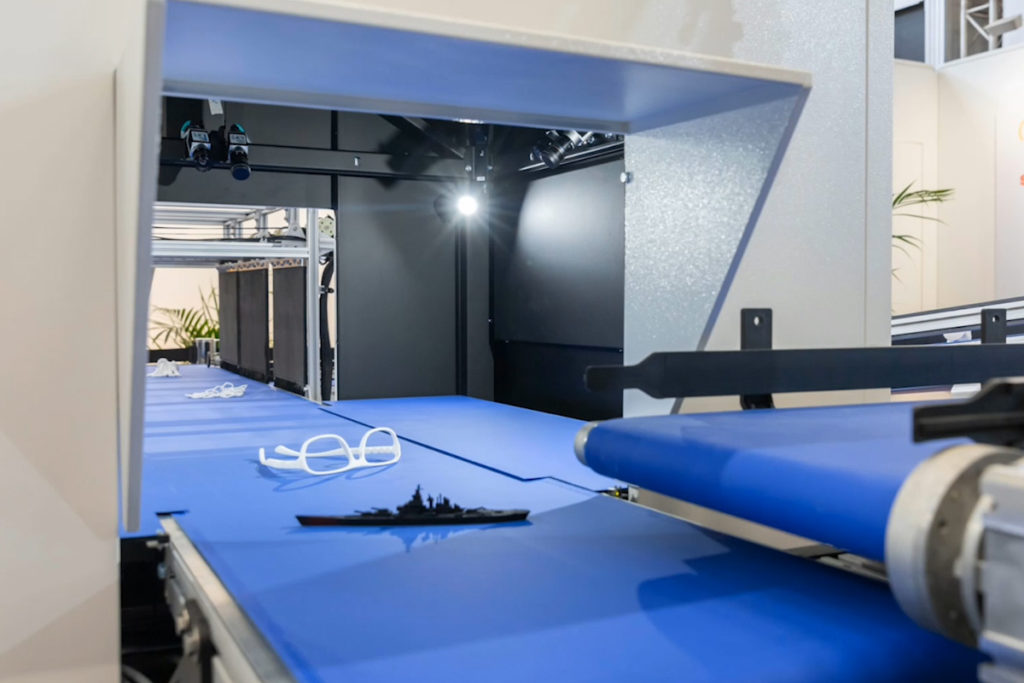

AM-Flow created a functional model (FUMO) of the AM Vision 2.0 system, with the software at the core of this prototype. The FUMO proved the functionality of the system; the search algorithm worked flawlessly. However, the hardware needed further improvement. Additionally, the system had to be designed for fast and efficient series production.

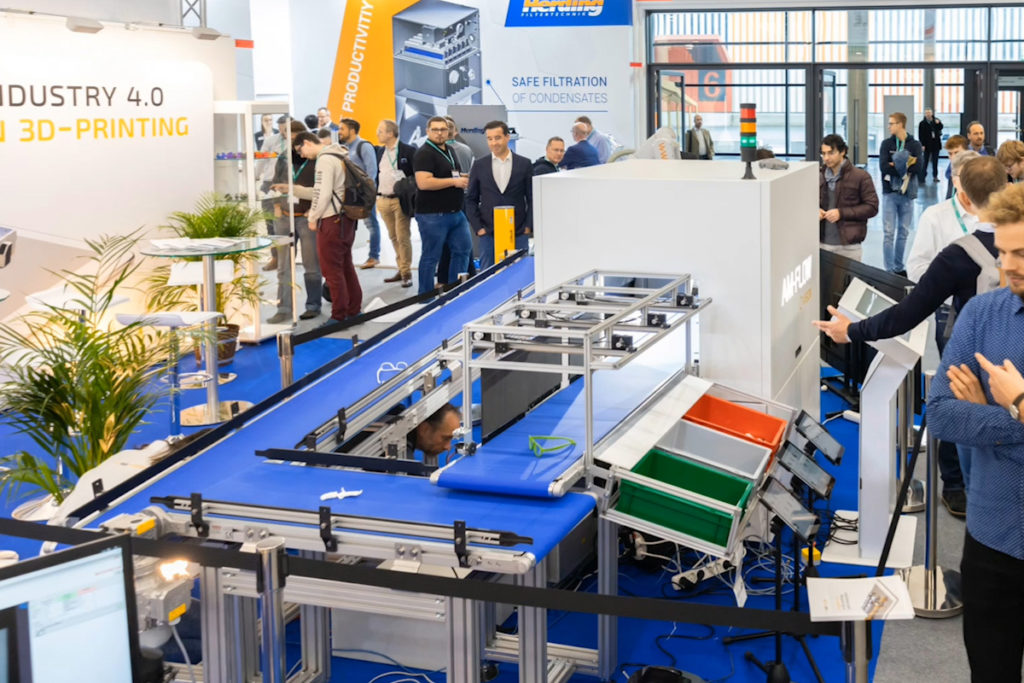

Potential customers were interested in the prototype and recognized the added value it could bring to their factories. Customers were lining up and eager to receive the product as soon as possible. A fast time-to-market was essential.

Several phases are important to achieve the best end result:

The knowledge transfer during the development phase enables careful documentation of requirements and needs in the areas of mechanics, electronics, and software. Mutual trust is of utmost importance to complete this process. By being open and sharing knowledge, the quality of the system can be guaranteed. Feedback from MTA's industrialization specialist resulted in the creation of a system highly suited for series production. During this phase, close attention was paid to overall costs and the desired time-to-market.

The AM Vision 2.0 is integrated into the end user's existing architecture. Therefore, it was essential to develop a universal system capable of functioning alongside various existing conveyor belt systems. This was taken into account in the basic design of the AM Vision 2.0, allowing the standard system with preset dimensions to be produced in series. By adjusting features such as the number of cameras in the machine, a customized version of the standard system can be created for specific customers. Additionally, the software used in the AM Vision 2.0 can be easily connected to the conveyor belt's software system, ensuring that sorted items are directed correctly.

The European and American markets have different quality certifications. By ensuring that the machine meets both European CE certification standards and the UL certification standards of the United States, the system is ready to be launched in any country.

To design a system that functions optimally, AM-Flow chose to outsource the engineering and production of the entire system. By integrating and outsourcing the engineering and production process to a single party, a significantly shorter time-to-market was achieved.

The collaboration between AM-Flow and MTA combines the core competencies of both companies, ensuring the best possible outcome. While AM-Flow’s main strengths lie in software research and development, MTA excels in advanced mechatronics and the industrialization process.

"AM-Flow specializes in artificial intelligence and machine learning. We have developed a unique search algorithm for sorting 3D objects, which directly responds to market demand. However, the expertise to design a system perfectly suited for series production is not something we have at AM-Flow. To achieve the desired fast time-to-market, we decided to seek a partner who could assist us."

As an experienced system supplier, MTA is able to integrate engineering and production through industrialization, creating an effective process with short lead times. This is closely linked to a fast time-to-money, which is especially important for a start-up. The system is ready for series production and scaling, with optimal manufacturability and reproducibility.

MTA determines which components are crucial to achieve an optimal production process. Additionally, we utilize an international supply chain that contributes to a competitive integrated cost price.

"In close collaboration with MTA, we were able to create a system that directly responds to market demand. Moreover, the system can be sold worldwide. MTA's expertise in mechatronics and industrialization ensured that engineering and production were integrated into one efficient process."